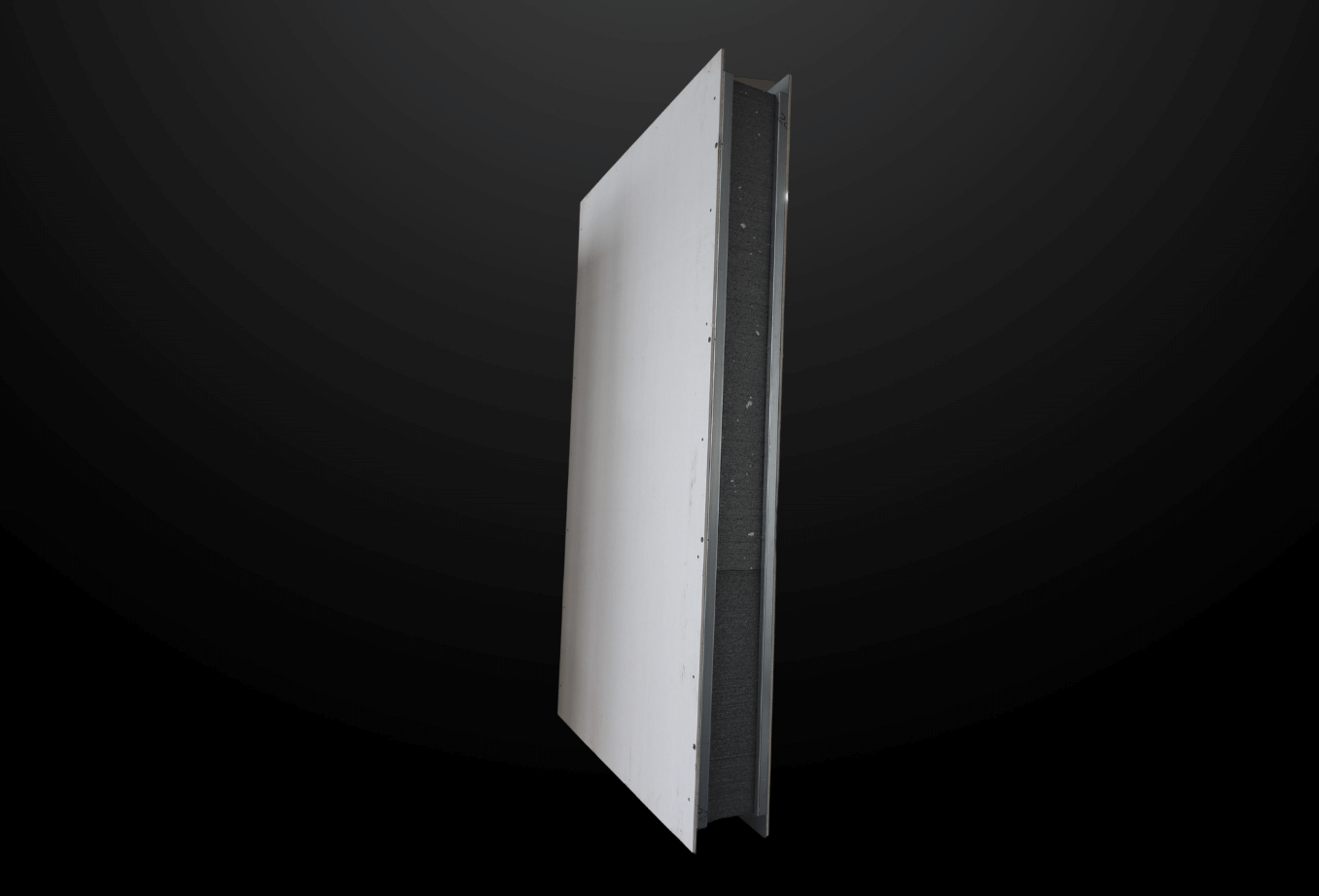

The panel illustrates the important components that come together to form a structural panel.

9mm - Magnesium oxide offers unrivalled fire protection and is highly resistant to flame, providing powerful and reliable insulation. In order to assess its effectiveness, the material was tested in accordance with the ASTM E136-16A standard - a method of testing materials within a vertical tube furnace at 750°C. The results were incredibly impressive; there was no change in the quality of the magnesium oxide, no change of state, no spread of flame or any indications of smoking whatsoever - demonstrating that it is an incredibly effective material.

Expanded polystyrene (EPS) insulation is a highly effective form of thermal insulation material and is an integral component of many exterior wall insulation systems. It is composed of small, sealed air bubbles that effectively work to trap heat, making it an ideal choice for keeping buildings warm in colder climates. EPS insulation boards have extraordinary durability as they are resistant to moisture

238mm wide

Zero Defects after 16 months Using the Panelised system. Semi-detached homes, London

Panelised systems offer a variety of benefits over traditional construction methods, making them an attractive option for builders and homeowners alike. Panelised construction offers advantages in terms of faster construction time, improved quality control, cost savings, energy efficiency, and design flexibility.

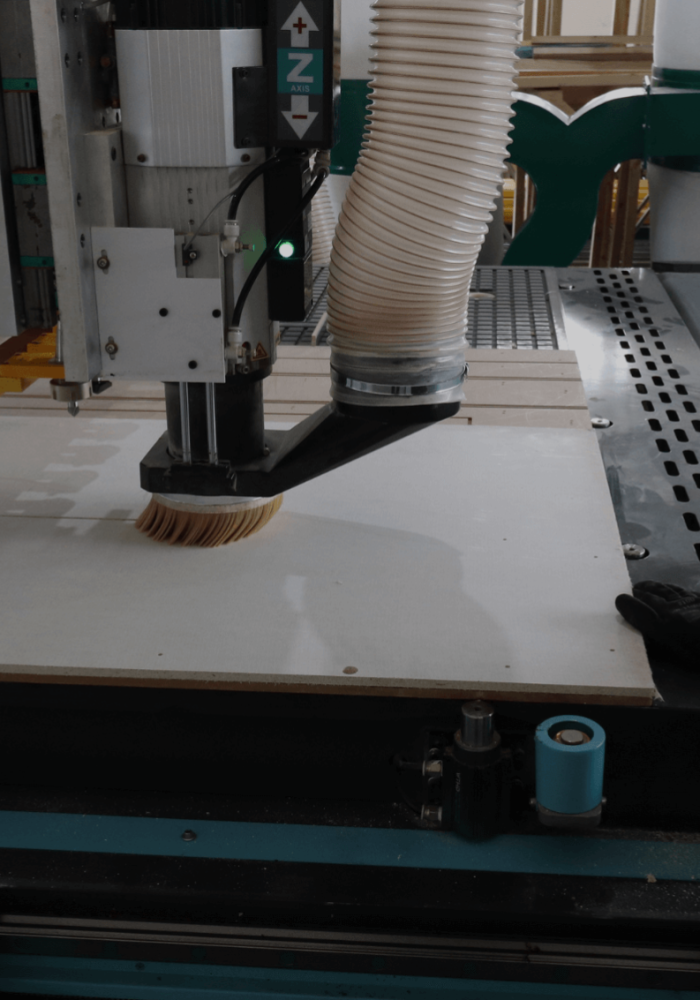

Faster Construction Time: Panelised systems can provide a faster construction timeline than traditional construction because the panels are pre-fabricated off-site and can be quickly assembled on-site. This allows builders to complete projects more quickly and efficiently as they don’t have to wait for materials to arrive on site or worry about weather conditions slowing down work. Additionally, because the framing components are factory-built rather than built on site, they are often made with higher precision than if they were manually constructed. This means that fewer mistakes occur during the assembly process and that time is not wasted correcting errors.

Improved Quality Control: Prefabricating panels in a controlled environment can result in better quality control than if the same components were built on site. Because the factory environment is usually indoors there is less risk of weather damage or other external factors affecting the product quality. Additionally, since all components are made in batches at a factory rather than individually on-site this can also help reduce potential errors or inconsistencies due to human error as it is much easier to ensure everyone follows the same standards in a controlled setting.

Cost Savings: The use of a panelised system can result in significant cost savings compared to traditional construction processes. For starters, labor costs tend to be substantially lower when using panelised systems as much of the work is done at a factory rather than on-site by manual laborers. Additionally, there may also be savings related to waste reduction as excess materials do not have to be transported from one job site to another and thus are not wasted as easily during each build cycle.

Energy Efficiency: Panelised systems can offer superior energy efficiency when compared with traditionally built homes due to their advanced design techniques which allow for better insulation and airtightness within walls, roofs and floors of buildings. They also often include technology such as photovoltaics which aids in energy production while still providing all necessary building components such as windows and doors – further increasing their overall energy efficiency rating where traditional builds may not be able to reach those levels without additional components or modifications being added after completion of the project.

Design Flexibility: In addition to offering superior energy efficiency ratings panelised buildings also offer greater design flexibility for architects and engineers when compared with other methods of construction such as stick framing or blockwork structures – both of which impose certain limitations on what type of design elements can be incorporated into any given project due to inherent structural constraints associated with their respective designs. Panelised systems however offer more freedom when it comes to creative customisation – allowing architects greater leeway when it comes to designing unique features suited specifically for any given project while still utilising standard materials within its walls, and roofing structure.

Panelised systems provide an ideal solution for constructing dream projects, as they are fast, simple and stylish compared to traditional building methods. As opposed to other construction techniques that can be labour-intensive and time consuming

“What the future’s built on”